Historical background

The fibers for concrete and building in general, in the broader and more general conception of the term, certainly cannot be called an invention of the present day. In fact it is possible to consider them as old as the concrete itself, if not even older! Ancient finds of dwellings, dated almost 2500 BC and dating back to the Mesopotamian civilizations, were made of clay mixtures and used straw as a “structural” armor. Other practices such as the manufacture of clay or mud bricks, with the addition of straw as a cohesive, have been applied since the time of the ancient Egyptians. Not only that, the Inca and Maya civilizations used to add vegetable fibers to their pottery to prevent them from cracking during the sun drying phase.

The primordial forms of concrete as we know it today can be traced back to the “opus caementicium“: A building technique used by the ancient Romans long before the year zero and based on the use of pure lime for the production of building mortars, later improved with the introduction of “pozzolana” in the compound as a binder (the hydraulic mortars). Since that invention, concrete has been added with fibrous elements that improve its quality, going against the formation of cracks and fissures. Examples of concretes and masonry added with ‘fibers’ can be found in the most disparate works: the so-called fibers were often made of waste materials such as straw, wood fibers, pig hair, cattle or horsehair. Surprisingly, the practice of adding mortars and plasters with animal hair or vegetable fibers has persisted over the centuries and was applied (even in Europe) even up to the beginning of the twentieth century.

The stimulus to find new solutions, which could respond to the anti-cracking requirements in an industrial way and without resorting to any kind of expedients, led at first to the use of asbestos and glass fibers. The first, structurally a good solution and with a low production cost, introduced in the United States since the first half of the 20th century, were obviously abandoned when the damage that asbestos caused to human health became known. The glass fibers were also officially invented in the United States in the 1930s, although there are indications that a similar product was being developed in the same period in Russia. Glass fibers are still used today as an additive for mortars and cement conglomerates.

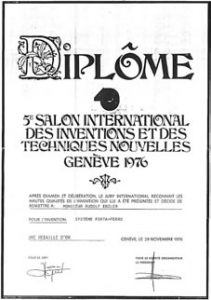

Starting in the 1960s, were developed various other types of fibers that could effectively replace or complement those already present, possibly that could be industrially produced, that had low costs and obviously had no undesirable side effects. Since then the research in the field of fibers for cement or lime based conglomerates has tried with the most disparate technologies: steel fibers, glass fibers, vegetable fibers, synthetic fibers have been developed and gradually up to solutions such as carbon fibers, basalt, aluminum or kevlar. Among the various types of fibers for concrete, we have to remember given the enormous diffusion that they still have, steel fibers and synthetic fibers. About steel fibers we can say that they are a simple, and nevertheless brilliant, reworking in the form of a filament of a material that has been combined with concrete since the first applications of reinforced concrete, the steel reinforcement in fact. As for the latter, the story goes back to the mid-1970s, when a Swiss engineer named Rudolf Enzler decided to apply the advances made in the study of polymer chain to the field of building fibers. In fact, at the 5th Geneva International Show of Inventions in 1976, the “Iron-Strong System” of the engineer Enzler won the gold medal. The first fibers in polymeric material for concrete reinforcing were born.

Since then, the polymeric fibers have carved out an exceptional place in the panorama of reinforcing fibers for concrete. Obviously, over the years, progress on synthetic fibers has not been lacking: from the first polypropylene fibers we have moved on to experimenting with different polymers, shapes and sizes. The structural fibers have recently been added to the auxiliary synthetic fibers, capable of giving the concrete a residual post-cracking resistance!

As for the Italian panorama, the history of synthetic concrete fibers for commercial use began back in 1982, the year in which the first premixed fiber-reinforced mortar was made. It was the coating of an Enel canal in Villadossola, performed with a thixotropic cement mortar, decidedly innovative as it was precisely fiber-reinforced and modified with silica fumes, developed by Eng. Edoardo Mocco.