CE marking for steel fibers (EN 14889-1)

One of the most important references contained in this standard is certainly that of characterizing the effects of the addition of fibers to the bending strength of concrete. The standard in this case is EN 14651 (see below).

CE marking for synthetic fibers (EN 14889-2)

The standard EN 14889-2 represents for the synthetic fibers what the 14889-1 is for steel fibers! This is also the case with the CE declaration of conformity. The standard on synthetic fibers differentiates two distinct certification methods applicable to fibers: fibers for general applications, System 3, and fibers for structural applications, System 1.

SYSTEM 3

The CE marking for synthetic fibers with the “3” certification system is based on the assumption that the fiber in question will not be used for structural purposes. The most important tests to be performed are the tensile test on the fiber (EN 10002-1) and the test on the effects of the fiber on the consistency of concrete (EN 12350-3). Both described later.

In this type of certification the fiber is subjected to a few tests, simple and inexpensive. Furthermore, any technological laboratory for building materials can carry out tests and issue the certificate. System 3 is therefore a rather easy type of certification to obtain: in fact it is a simple self-declaration, issued by the supplier, of the fact that the values reported in the declaration of performance are true. Furthermore, there are no limit values to be respected or exceeded, therefore any fiber can be marked with System 3.

SYSTEM 1

The marking according to EN 14889-2 with System 1 was designed to test and certify fiber compatibility for structural applications. The procedure for obtaining this certification is a direct derivation of that used to certify steel fibers with EN 14889-1.

Unlike the marking with System 3, the System 1 requires that the tests be carried out by a notified body with ministerial authorization and that the material samples are taken by an inspector of said body directly at the supplier production site. In addition to all the tests required for System 3, the 1 also requires the characterization of the behavior of a beam subjected to bending, according to the EN 14651 standard (the same used for steel fibers). This test is expensive, complex and time consuming to obtain. Furthermore, unlike System 3, in this case there are minimum values to be respected, so not all fibers can actually be marked for structural applications.

In summary, this type of certification is extremely more prestigious than the marking with system 3. Despite this, the only real difference between the two is a small number written somewhere in the declaration of performance or in the technical datasheet (if present). It is therefore important to be able to distinguish the two types and recognize when a fiber is certified and when not.

Requirements for mix design (EN 14845-1)

This legislation defines the raw materials to be used for the construction of fiber-reinforced concrete mixtures, the mix design, the additives to be used, and prescribes how mixing and subsequent curing are carried out. This standard ensures that the tests for marking EN 14889-1 and -2 are always carried out in the same way and starting from the same concrete (at least in theory).

Effect on consistency (EN 12350-3)

The CE marking for synthetic fibers requires the measurement of the consistency of fresh concrete on two mixtures: one added with a certain quantity of fibers and the same formula without fibers. The difference between the consistency of concrete with fibers compared to that without fibers indicates the effect of the introduction of fibers into the mixture. This value is particularly interesting for pavers and those who will have to “work” fresh concrete.

The technique for testing the consistency of fresh concrete is that which in technical jargon is also called “Vebè test”, defined by the standard EN 12350-3. To carry out this test, a normalized fresh concrete cone (Abrams cone) is placed on a circular plate, the plate is vibrated with a well-defined procedure and the time taken for the concrete to “expand” beyond a certain radius is measured. Less time is measured, lower concrete consistency will be.

The value reported in the declaration of performance issued by the laboratory is the difference (measured in seconds) between the time of Vebè found with the mixture without fibers and that with the mixture added with fibers. Smaller this difference is, lower is the effect of the addition of fibers to the concrete.

Tensile strength (EN 10002-1)

The tensile strength of the single fiber, normally given in the technical data sheet, carried out according to the EN 10002-1 standard, is a measurement made on the fiber by itself, before it is inserted into the concrete.

The breakdown strenght is measured by inserting the fiber in a machine that lengthens the fiber until it breaks. The force that the machine has had to exert to break is divided by the surface of the section of the fiber, thus obtaining a tension. The unit of measurement is often indicated in MPa (megapascal) or even N/mm2, the two units of measurement are equivalent.

Bending resistance on beam (EN 14651)

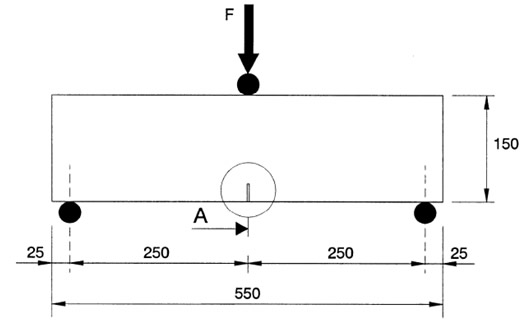

With this test we measure the bending strength (and by extrapolation we also measure the tensile strength) of a concrete beam added with structural fibers. The test is prescribed both in the CE marking of steel fibers and of synthetic structural fibers (System 1).

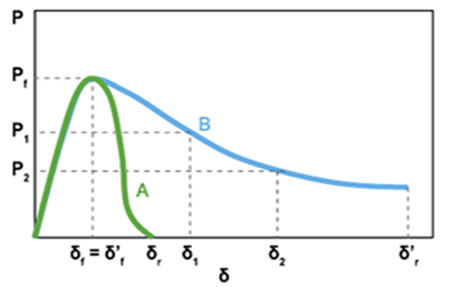

The measurement of the force exerted by the press as the fissure opening at the extrados increases gives us an indication of the behavior of fiber-reinforced concrete when the structure is, statically speaking, “in crisis”! The force graph as a function of the crack opening is normally the one shown above. Note the difference between curve A which is typical of concrete with non-structural fibers (or without fibers) and B which instead represents the joist with structural fibers. The graph also shows an initial zone in which the curve is the same in both cases: this phase, in which the curve of the tension rises quickly and almost vertically, describes the joist in its classic pre-cracking behavior, before get cracked. Once past the breaking point, the resistance curve undergoes a sharp drop and from this moment on the action of the structural fibers becomes evident.

Typically in this type of test the residual strenght values are measured for two crack opening measurements: at CMOD1 and at CMOD4, that is when the opening of the crack at the extrados is increased respectively by 0.5 mm and 3.5 mm respect to the initial situation. The acronym CMOD stands for crack mouth opening displacement: it would be the opening of the crack at the joist and it is the measure used as an abscissa in the graph displayed.

A fiber that wants to be structural must bring the joist to exceed the values of 1.5 and 1.0 MPa, respectively at 0.5 and 3.5 mm of CMOD. The dosage thanks to which the fiber passes the test will be the characteristic dosage of the CE marking of the fiber itself.

Square plate test (EN 14488-5)

There are several versions of the plate flexure test, depending on the regulations applied. The European standard is described in the EN 14488-5. This standard requires the production of a flat test piece 60 × 60 cm per side and 10 cm thick. The test piece rests on the perimeter and a press presses it to the center, until it is completely broken.

The bending resistance test on a square plate is usually prescribed by the designers in the case of structural sprayed concrete in the tunnel. This laboratory test was in fact designed to simulate the effects of rock subsidence in a tunnel, where a coating with spritz-beton was performed inside. In a similar situation, in fact, there is a concrete slab on which pressure is exerted.

It should be noted that the square plate test is not prescribed by the EN 14889 standard on structural fibers, therefore it is not essential to carry it out for the purposes of CE marking and the values obtained are not reported in the CE declaration of conformity.

Future evolution

It seems that the future of fiber-reinforced concrete should change within a few years, judging by the signals sent by national and European legislators. Increasingly, the procedure for using fibers will be that for which the designer will no longer tell how many and which fibers to use in a certain work, but rather will prescribe in his specifications the type of concrete to be used.

We explain better: in the 1990s, in Italy, there was a transition from traditional “dosage” concrete to “resistance” concrete. The initial market situation saw companies order the concrete at the concrete plant directly indicating how many kg of cement to use in the recipe; following the regulatory change, this practice was interrupted and the companies began to order the concrete requesting the service, regardless of what the recipe was and how many kg of cement were used. It had become the task of the concrete plant to know how to get that service and guarantee it.

Likewise, with fiber-reinforced concrete, the situation will probably undergo a similar evolution over the next few years. The “toughness” classes of the fiber-reinforced system are already described by recent regulations. Based on these indications, a concrete is classified based on the maximum resistance achieved in the bending strength test, and by the behavior of the post-cracking section.